MICROSCOPY HAS NEVER BEEN SO EASY!

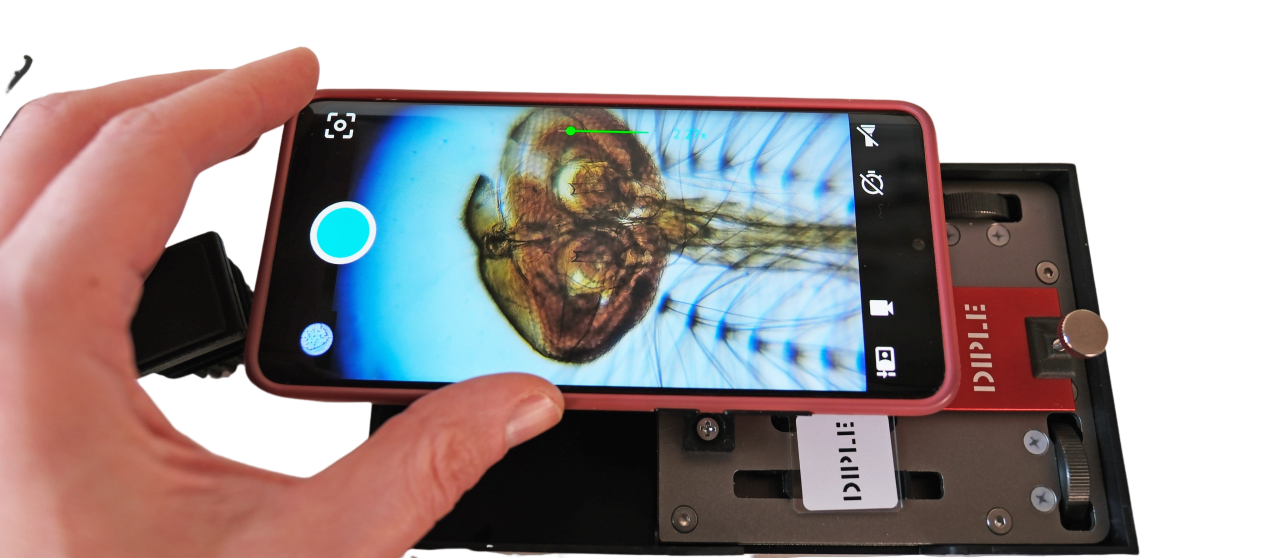

DIPLE is an innovative product that converts any mobile or tablet into a digital microscope.

DIPLE allows everyone to see the microscopic world, in a new way. It is not a standard microscope; it is compact and portable. Here you can find instructions and tutorials, plus a troubleshooting table; inside the table you can find links to video for solutions of specific issues.

VIDEO TUTORIALS

TROUBLESHOOTING TABLE

| EFFECT | CAUSES | SOLUTIONS |

|---|---|---|

| Shaded lines or spots | Stain on the frontal glass or on the rear glass | Clean the glass accurately, following the procedure in the VIDEO at this link. Materials: toothpicks; paper towel; water (or alcohol). |

| Fine stage not stable | a. Something under the stage | a. Remove all the parts under the stage, except the light source |

| b. Bumper for the light source not well in place | b. The light source is kept in place by the pressure of a soft bumper. If this bumper is shifted in a position out of its site, detach and reposition it under the level of the stage (photo) | |

| c. The stage moves inside the box | c. The tolerances of the box manufacturing could allow the stage to shake a little bit in its site. However, it is possible to reduce/remove this effect unscrewing the 2 screws in the pic and shifting the perimetral piece of plastic out of the aluminum plate border. VIDEO | |

| Lens tile unstable | a. Lens tile non tightened | a. Use the 2 blocks to press the sides of the tiles near its magnetic end and fasten them with the screwdriver. This will limit the backlash of the tile. VIDEO |

| b. Screw-thread clearance | b. In some cases the clearance between thread and screw, due to manufacturing tolerance, could allow unwanted backlash. In DIPLE, the screw-thread couple is not used to firmly join two parts; so the standard manufacturing tolerance could allow a little shake. It is easily possible to remove the screw-thread clearance with the same method used in other applications, for example with a piece of PTFE tape around the screw (tape commonly used for avoiding water or gas leakages from joints; alternatively, a little piece of thin adhesive tape can work fine). (VIDEO). | |

| Spins to reverse the motion of the glass slides | Clearance between the glass slide and its two holding parts (in fine stage) | The glass-slide holding parts have been designed a bit larger than the prepared glass slides into the kit (about 0.5 mm larger); this because we want to allow also the use of other standard glasses, that could be a little wider. For this reason, the user have to spin freely the knob some times to reverse the motion of the slide along that direction. You can find headless screws on the holding parts (for kit from mid-2025) to tune this clearance (VIDEO). |